This part describes the standard belt conveyor idlers of Nippon Conveyor, pre-manufactured according to Japanese Industrial Standards (JIS). Our idlers are always available, ensuring you can find the exact type that meets the technical requirements of your operations.

1. Features of NC Standard Idlers

Reading more “Features of NC Standard Rollers”

2. NC Standard Idlers

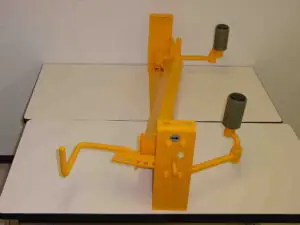

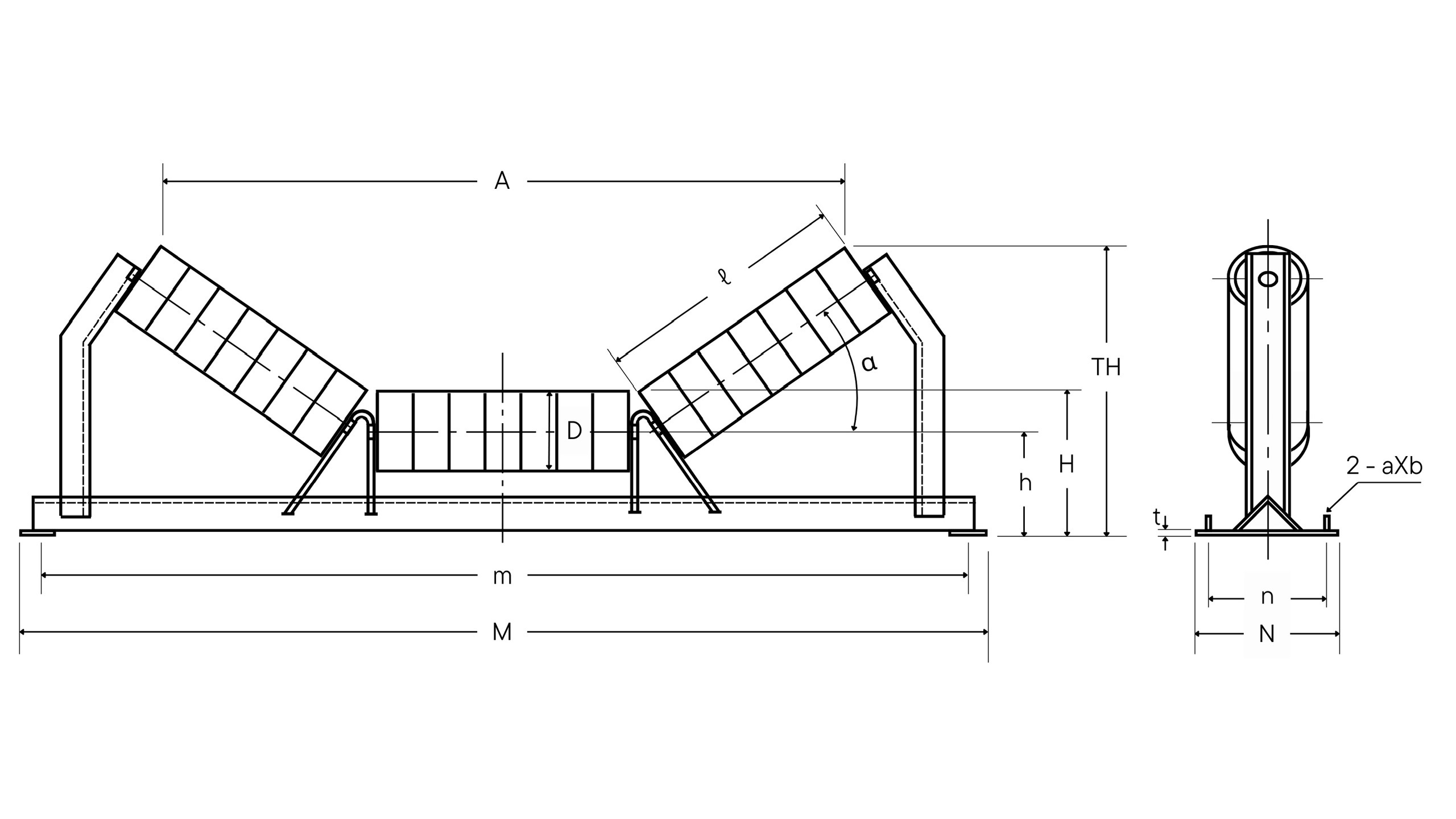

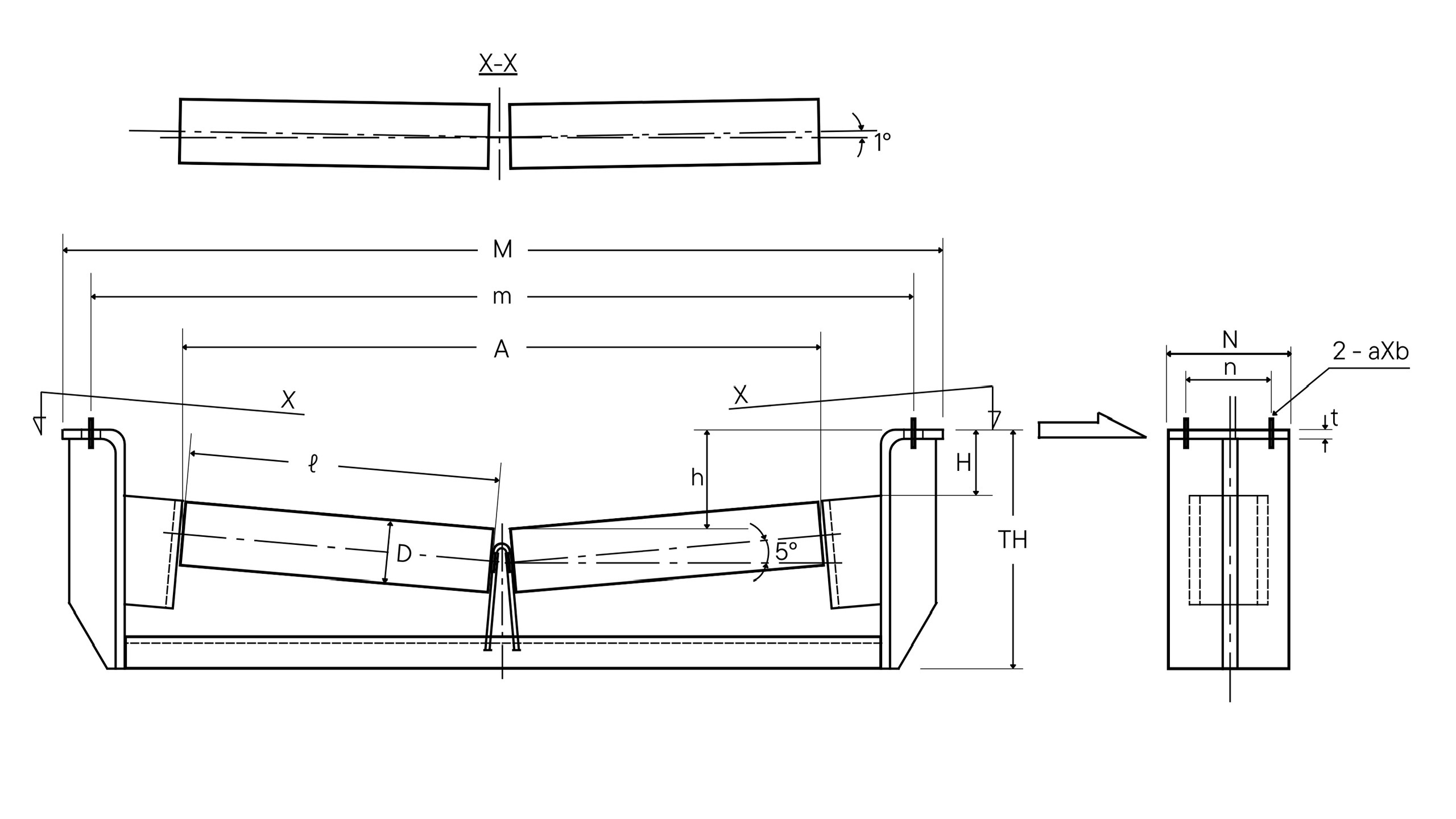

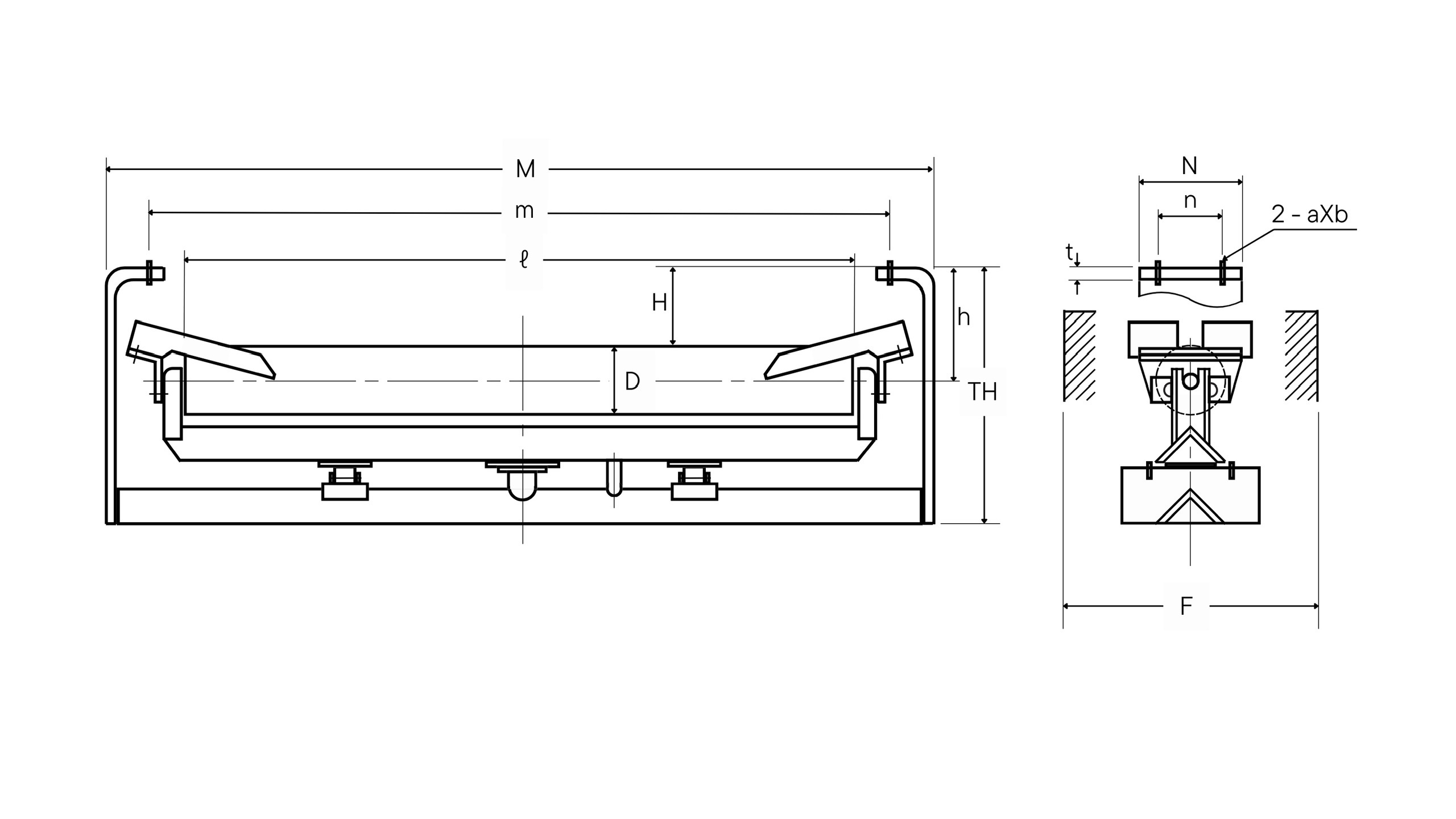

CJ - Troughed Carrying Idler CJ-G - Low noise Carrying Idler

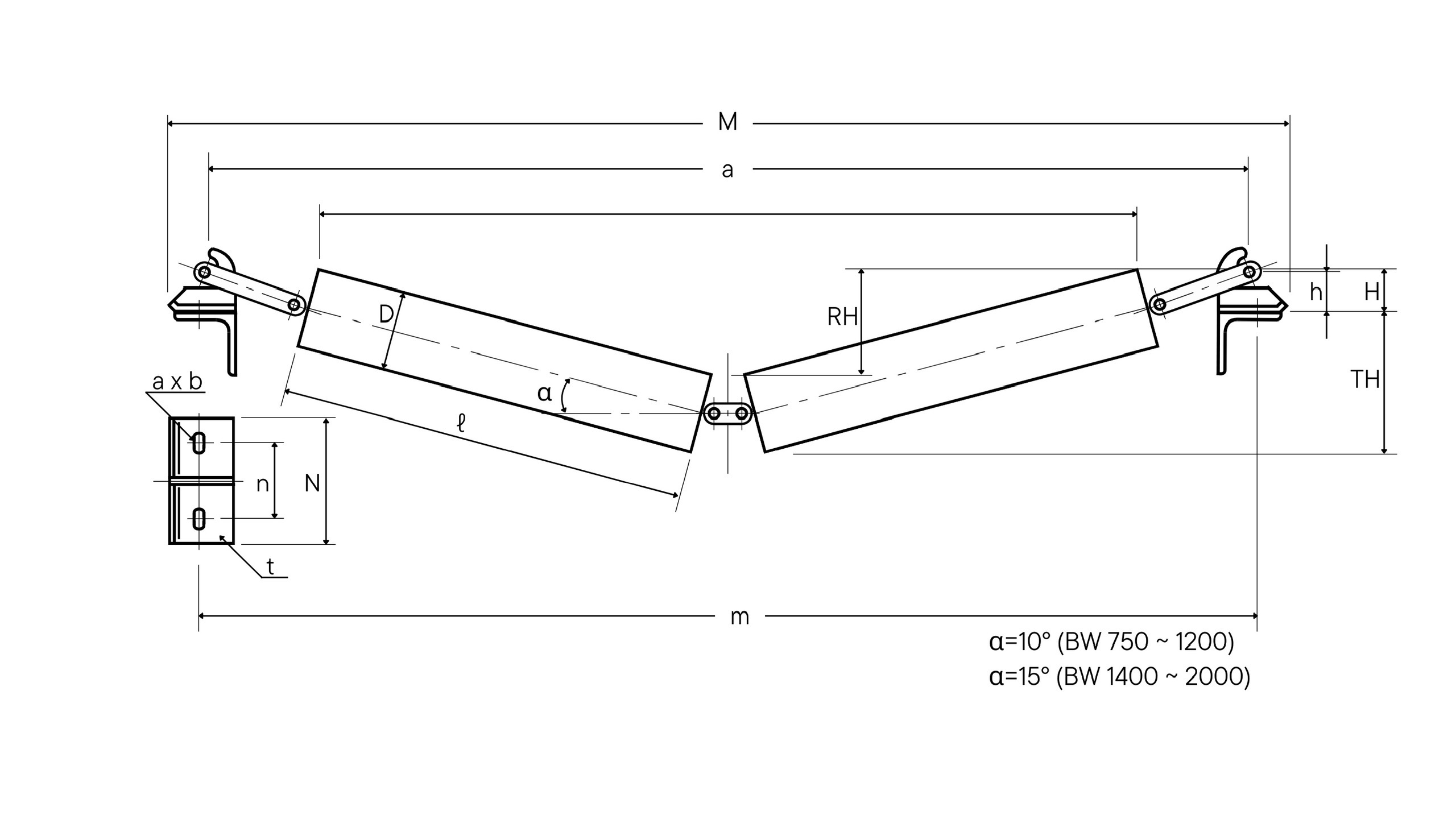

Standard carrying idlers given below are available to meet the required belt width and Trough angle.

Low-noise carrying idlers with lagged anti-abrasion rub-ber 6 mm thick on rollers finished by surface grinding.

The conveyor noise 10 decibel less than that of standard idlers, though varying with the speed.

Impact idlers for the loading point. Any model available to meet required belt width and trough angle.

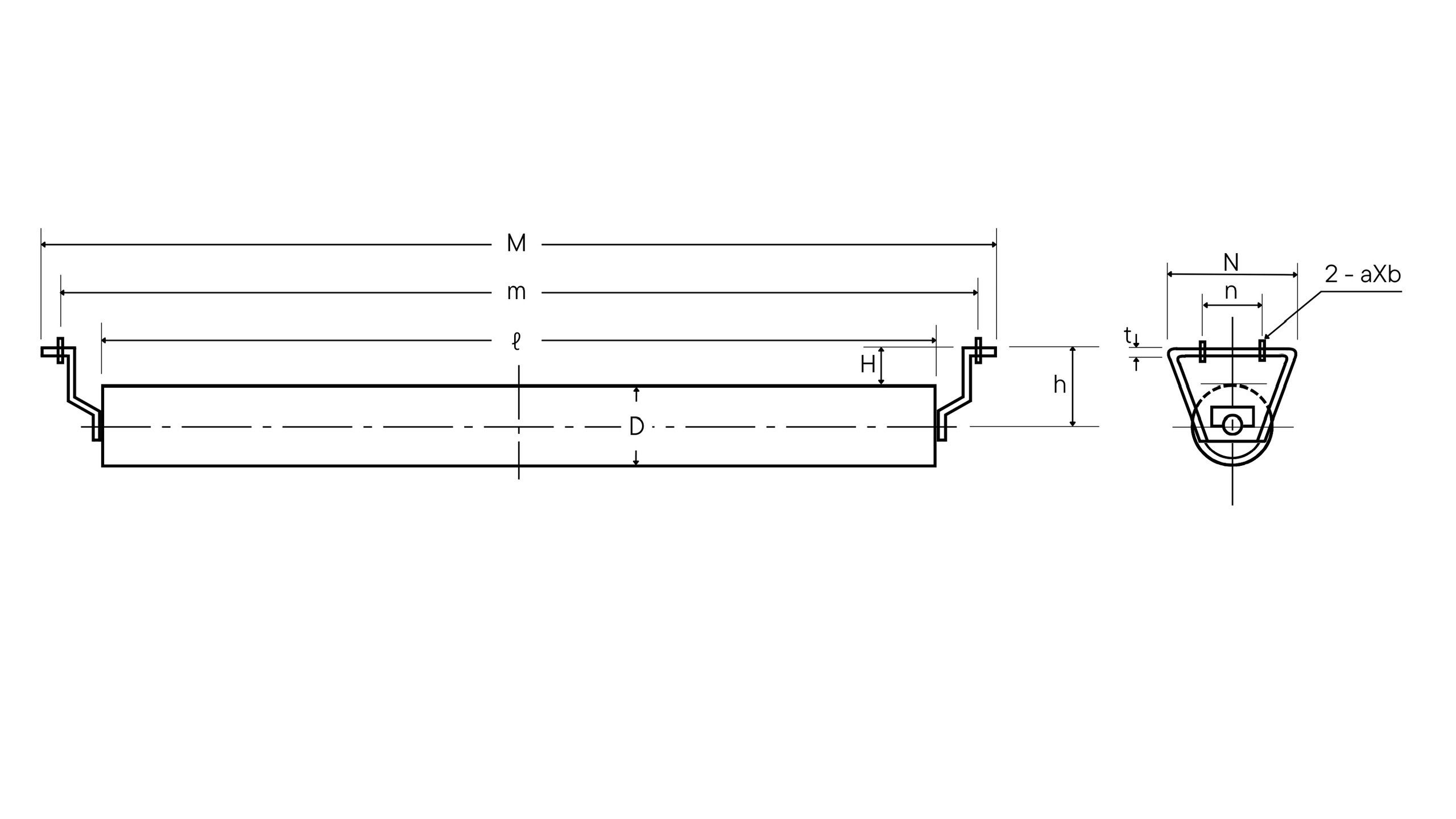

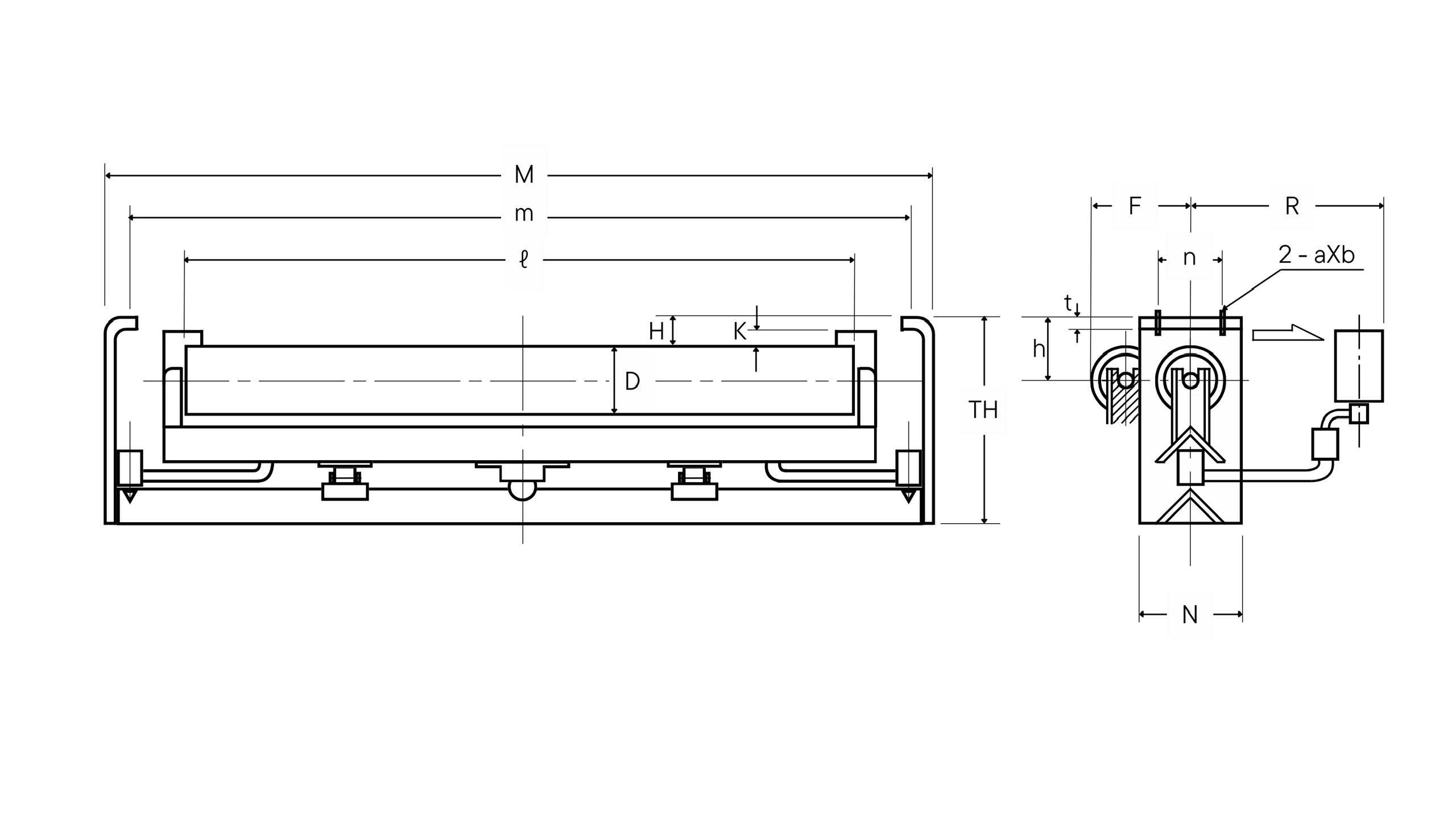

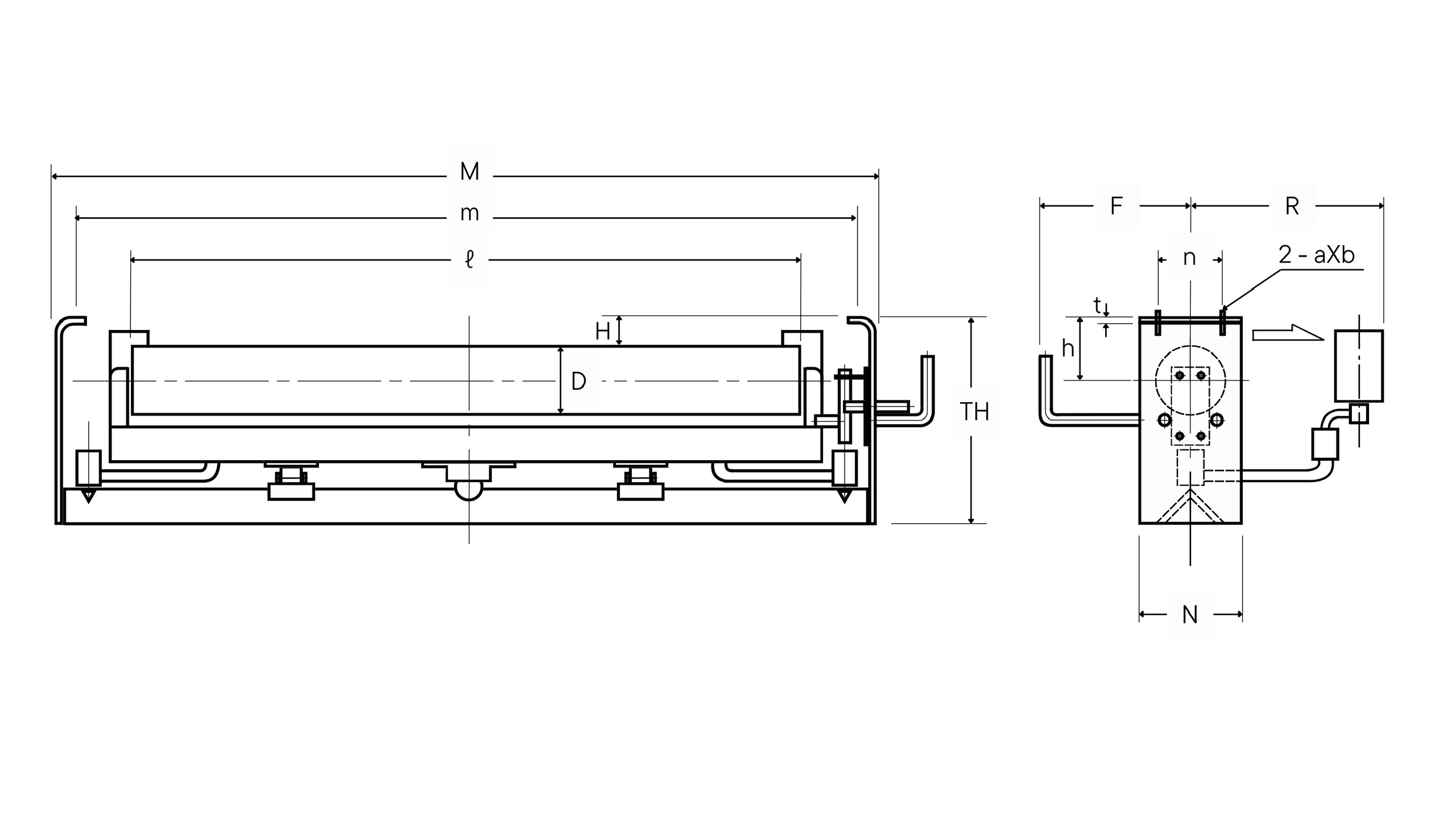

Flat return idlers, freely available to meet the required belt width and trough angle.

Low-noise flat return idler with lagged anti-abrasion rubber 6 mm thick on rollers, finished by surface grinding. The conveyor noise 10 decibel less than that of standard idlers, though varying with the speed.

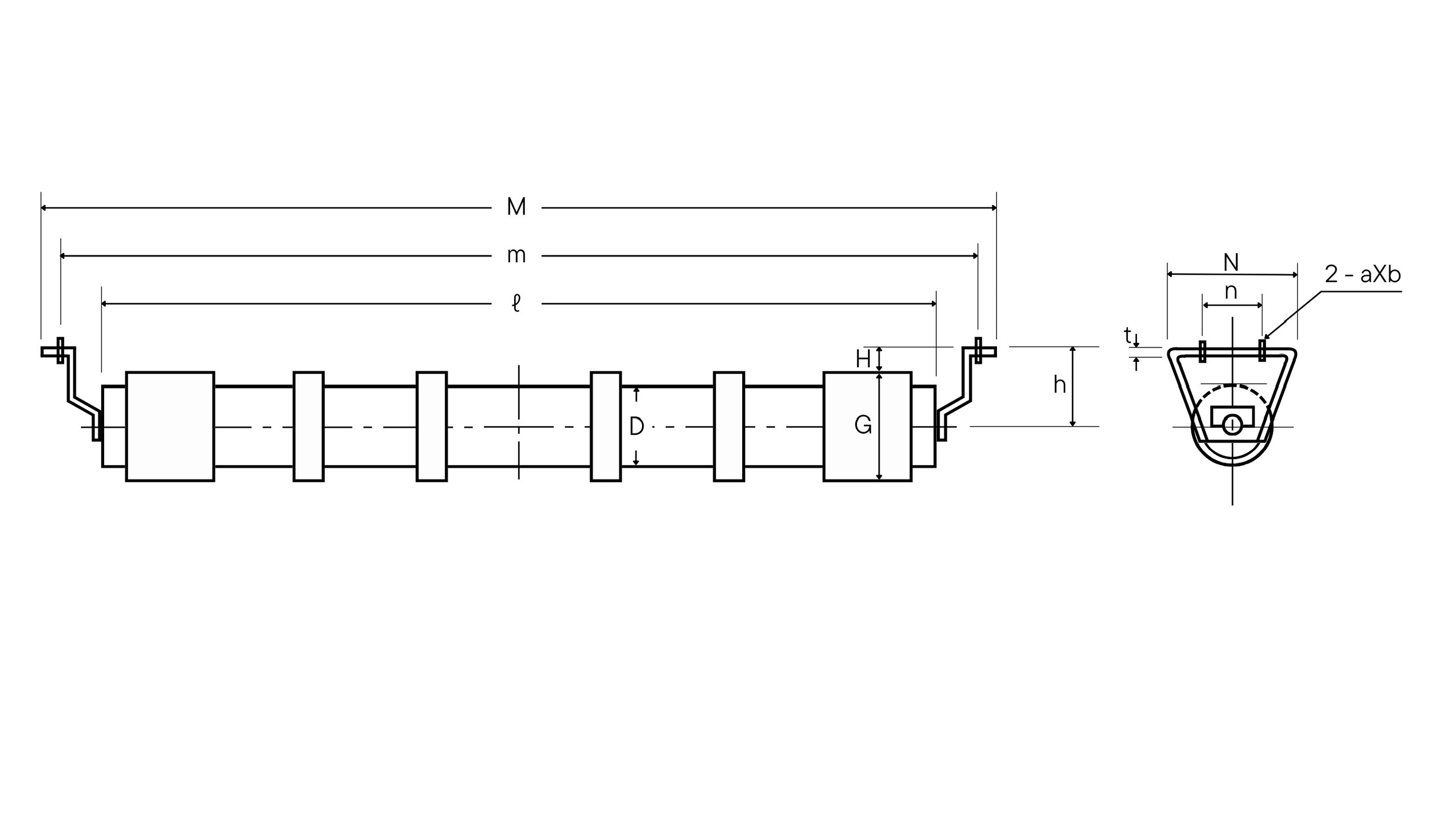

Return idlers with rubber rings to prevent any fine-grain on a belt from sticking to the idler roller or falling down to the floor.

Troughed return idlers with 2 forward- tilting roller. The belt training effect is given by means of tilting and troughing.

Low noise V return idlers with lagged 6mm thick anti-abrasion rubber on rollers.

The conveyor noise can be 10 decibels less than that of standard idlers, though varying the speed.

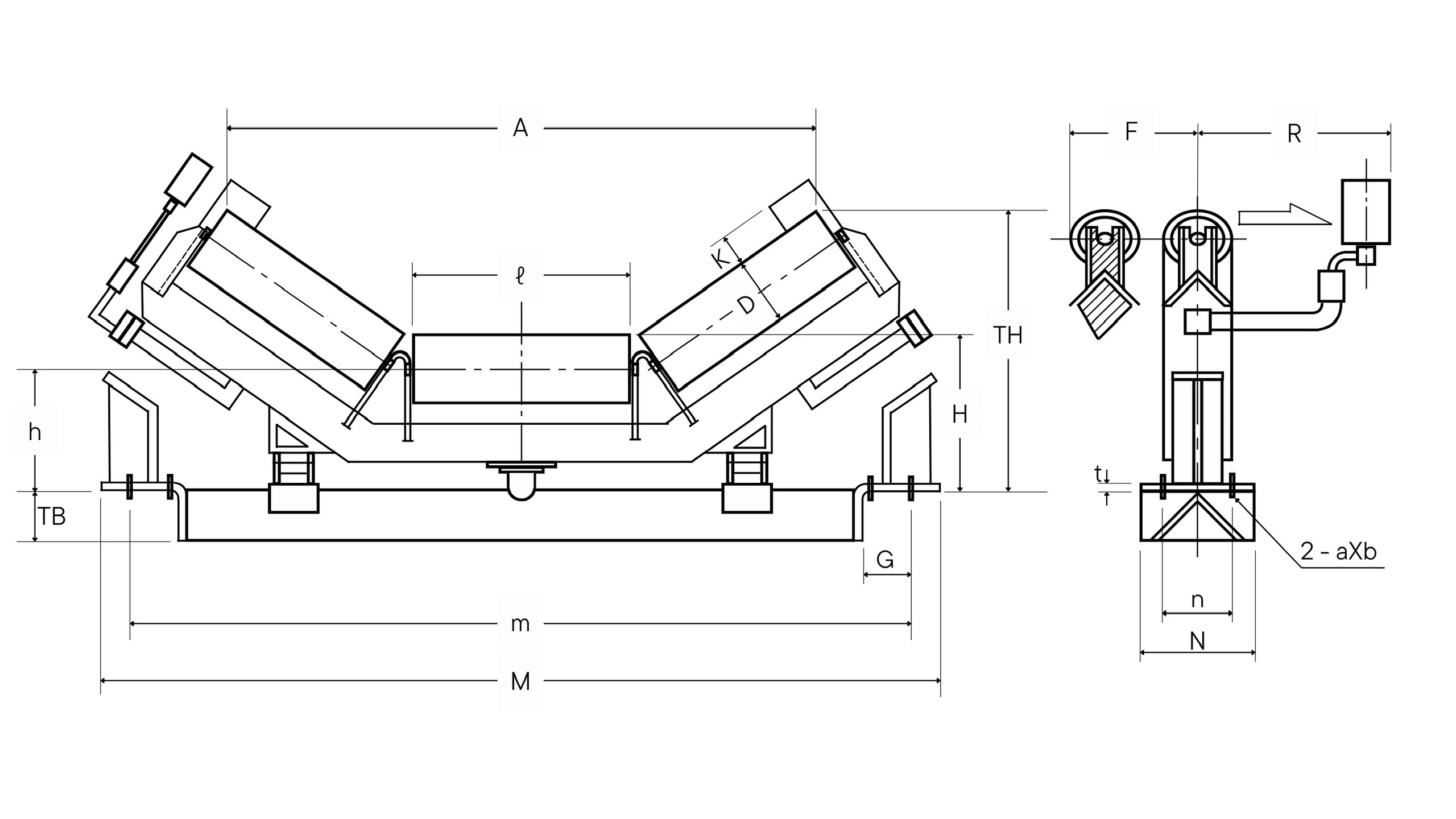

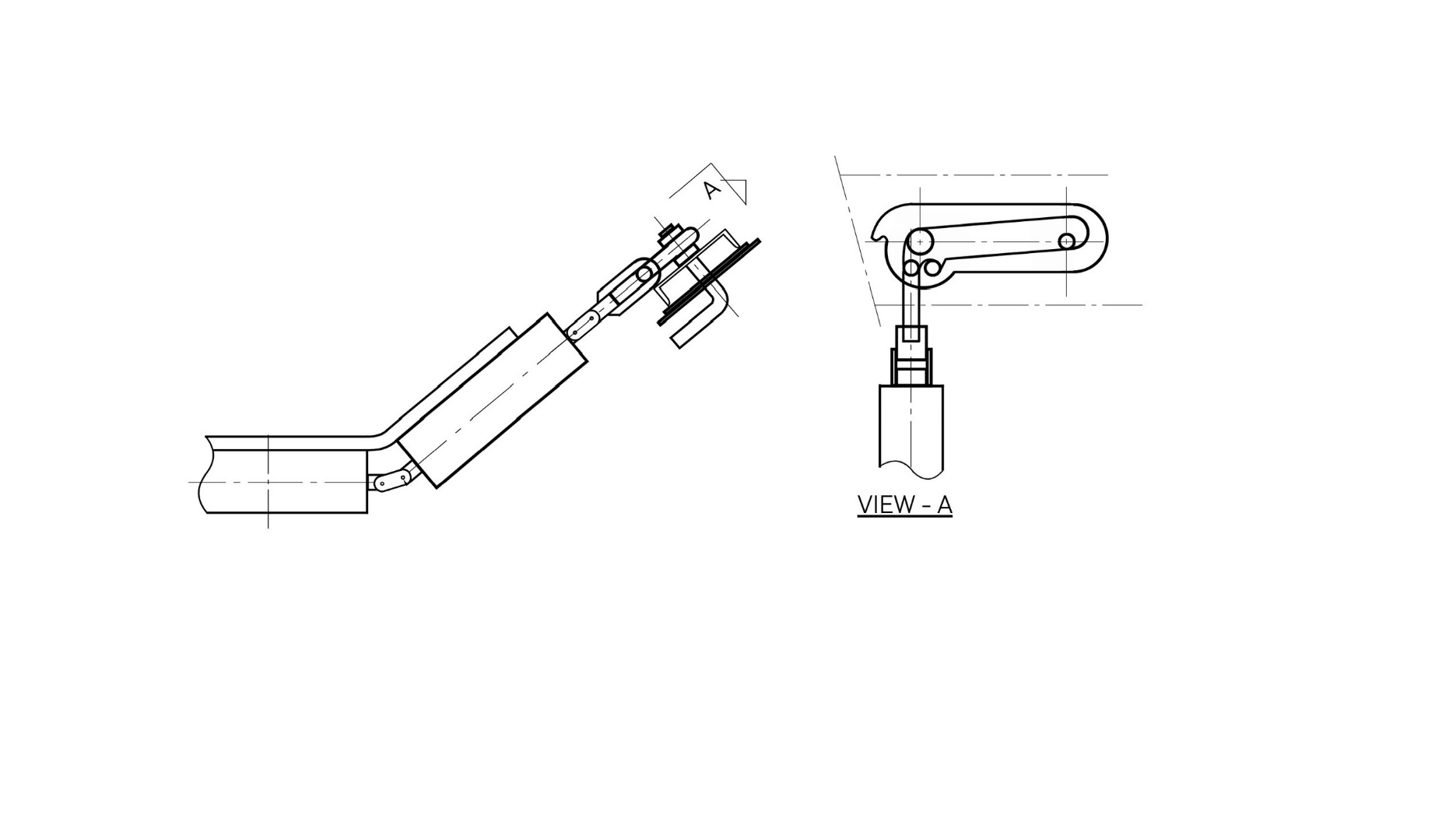

The linked mechanism is applied for forced operation. In case the off-line belt contacts the side rollers, the rollers are apt to return the belt back to the center for the off-line elimination. Pivot is designed to prevent rust and corrosion.

In case the off-line belt contacts the guide shoe, the rollers are apt to return the belt back to the center for the off-line element. Guide shoes of steel plates or ceramics can be provided as well as cast iron as a standard application.

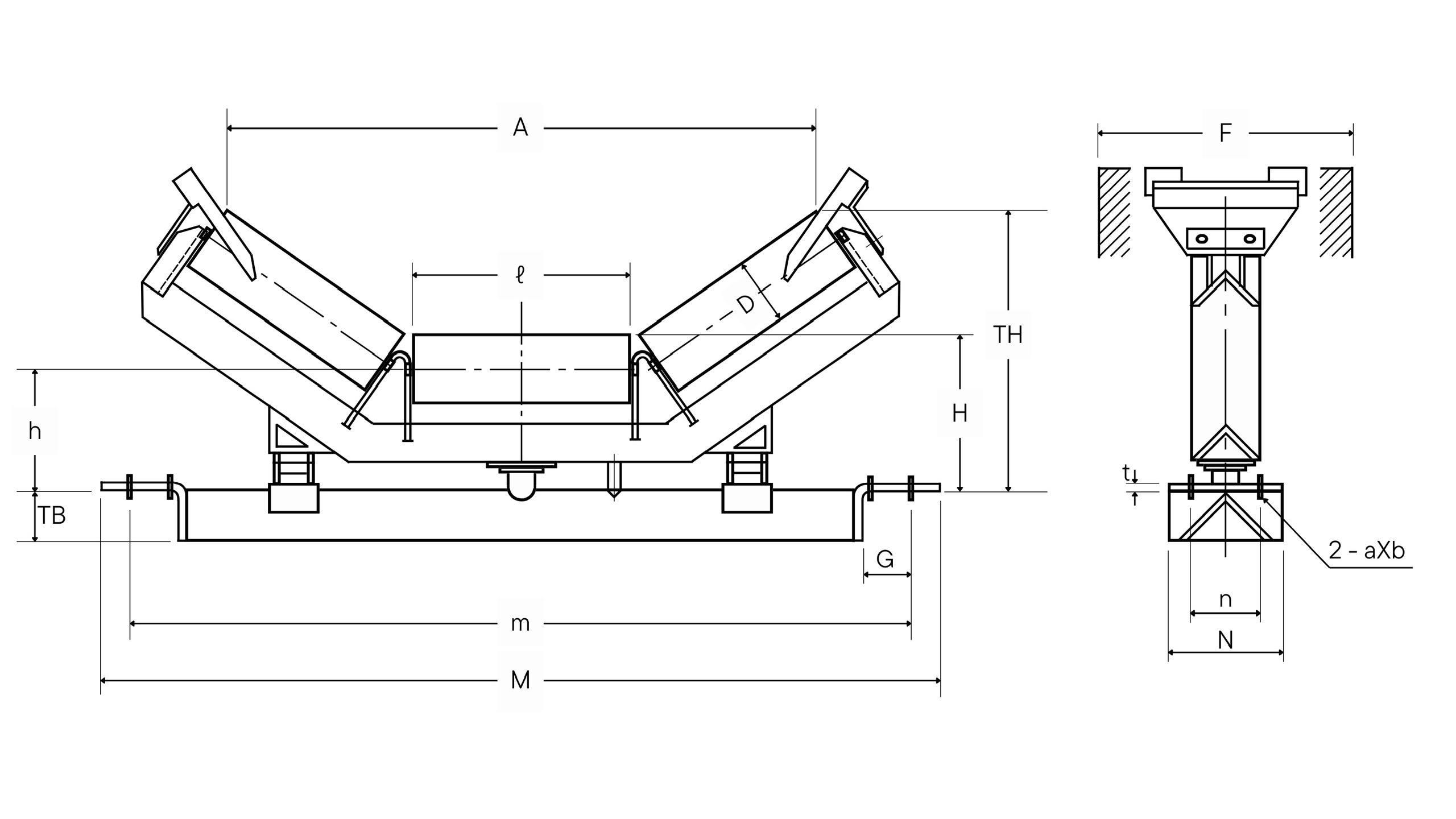

The linked mechanism is applied for forced operation. Belt training flat return idler which works in the same way as belt training carrying idlers, Model COL11 does. Pivot is designed to prevent rust and corrosion.

Belt training flat return idler for reversing operation, which works in the same way as belt training carrying idler Model COR does. Guide shoes of steel plates or ceramics can be provided as well as cast iron as a standard application. Pivot is designed to prevent rust and corrosion.

Belt training flat return idler which is fixable after belt alignment by means of manual adjustment.

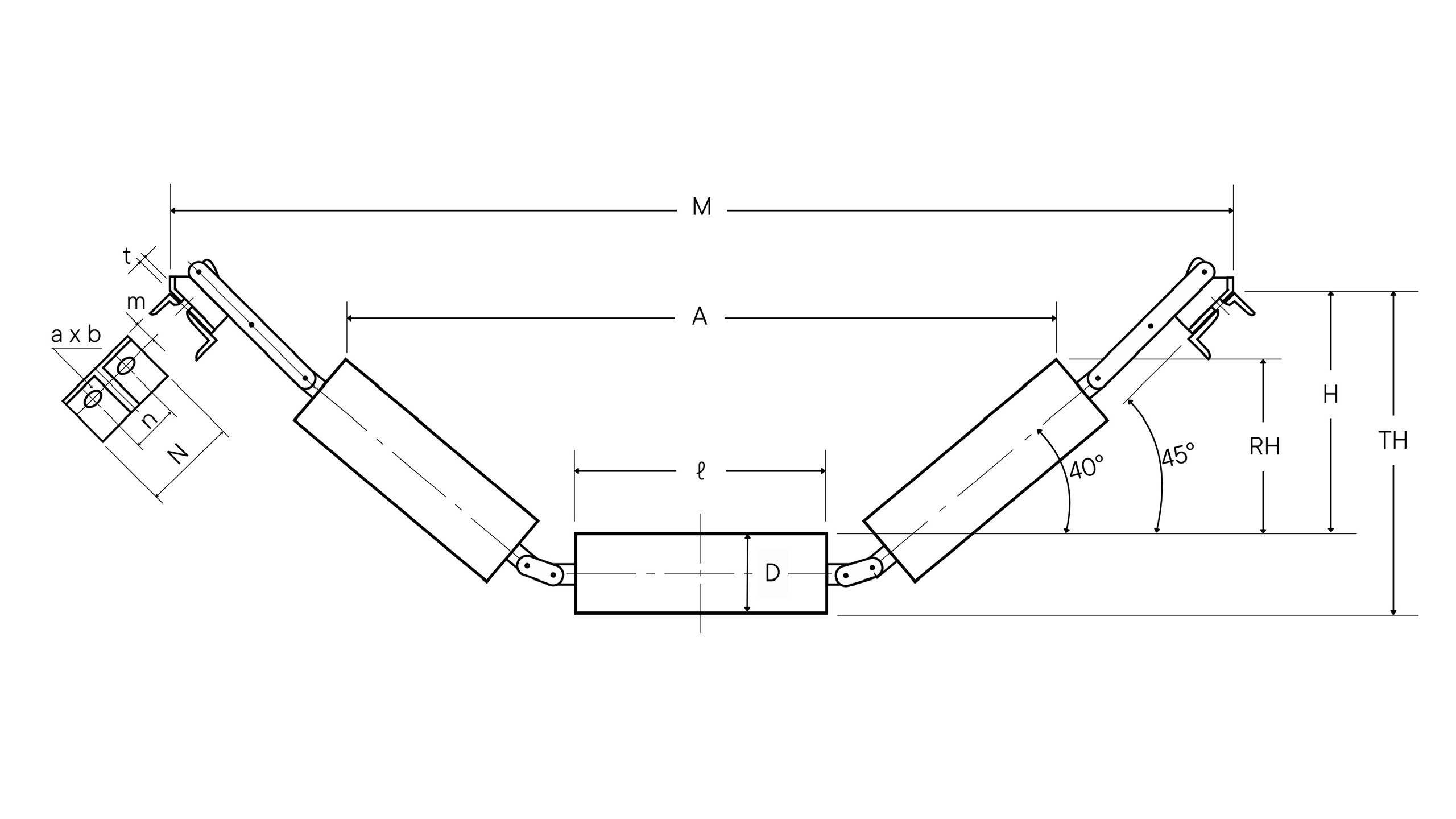

Garland carrying idler, which tends to move toward the center due to the mass of the belt and material handled. Flexible garland type is suitable for large-sized material.

Garland return idler, which tends to move toward the center due to the mass of the belt, resulting in preventing belt off-line.

3. Special Idlers

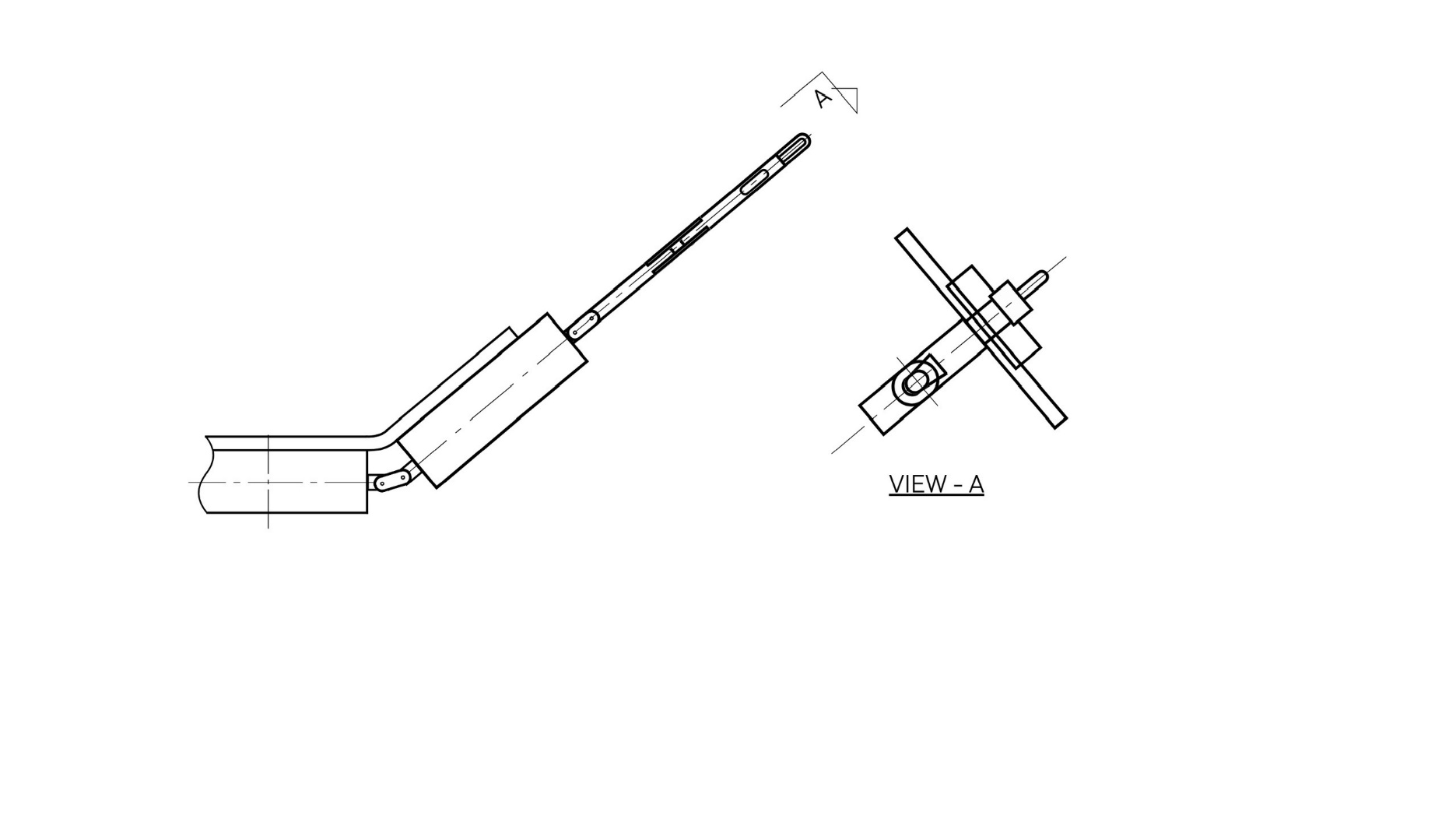

TGC - Garland carrying IdlerRollers freely move to cope with the imbalanced loading of materials or minimize any materials spillage. In case any breakage of the roller takes place, turn the holding lever of hangers to keep rollers suspended off the belt to prevent roller from heating up.

The displacement of rollers relieves any impact coming out of carried materials at the loading point, resulting in the longer life of the conveyor belt and rollers.

Tiếng Việt

Tiếng Việt