This part describes the standard belt conveyor rollers of Nippon Conveyor, pre-manufactured according to Japanese Industrial Standards (JIS). Our rollers are always available, ensuring you can find the exact type that meets the technical requirements of your operations.

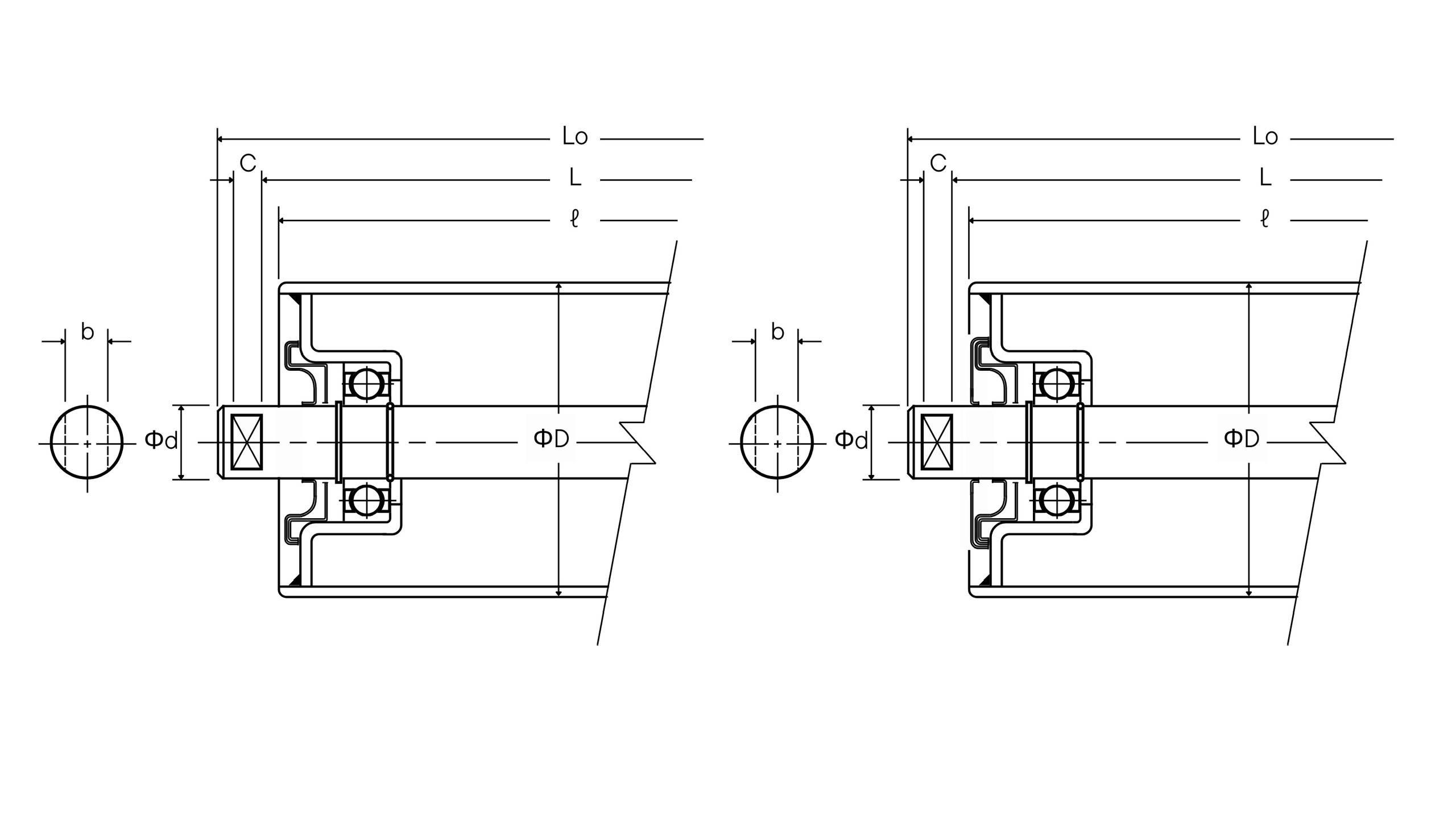

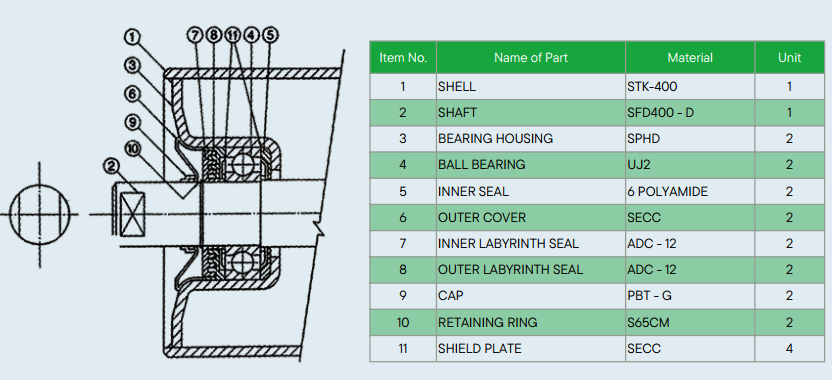

1. Structure of NC Standard Roller

2. Features of NC Rollers

Accurate pipe

Balanced Rotation for High Speed Operation Idler rollers are made of best-suited materials with state-of roundness and concentricity to ensure well-balanced rotation.

Out-of-rotational balance in our idler rollers is as following:

Accurate shaft

Cold Finished Steel Bars are employed for shaft material-al. Less gap tolerance than JIS stipulation gives no slippage between bearings and shafts under high-speed and heavy loaded conditions.

Low Friction Resistance and Energy-Saving

The frictional resistance factor of our idler roller itself to rotate (f) stays less than 0.01 though it varies with the roller dia. and bearing bore.

However, employ (f)=0.012 to 0.02 to compute overall friction resistance for calculation of conveyor drive horsepower in view of other operating conditions involved.

Permanent Lubrication by ZZ Shield Bearing

NC idler rollers are of factory-greased, sealed-for-life type, fitted with precision deep-groove ball bearings (with ZZ shields) at both ends. No extra-lubrication is required.

3. NC Standard Rollers

CMFR - Carrying Idler Roller CMFR-G - Low noise Carrying Idler RollerDimensionwise is the same as described, except for roller diameter with an additional 12mm

NC Standard Impact Idler Roller equipped with a hollow rubber block. Rollers for belt width 750-1200 mm are provided with one bigger size bearing to increase.

IMFR-J is a middle-duty model impact idler roller installable to the carrying idler frames.

Dimensionwise is the same as described, except for roller diameter with an additional 12mm

GMFR is designed for heavier belt support, to prevent grains on the return belt from falling.

GMFR-J is designed for light or medium-weight belt support, to prevent grains on the return belt from falling.

The intermediate ring is made of urethane with superior antiabrasion, leading to a longer life.

The same dimension for mounting as the return idler roller with rubber ring has.

Dimensionwise is the same as described, except for roller diameter with an additional 12mm

This roller is used precisely molded thin steel plate material for a labyrinth seal instead of resin (plastic) material. Thereby, the roller becomes recyclable as ironware when it is scrapped. Moreover, the outbreak of fire from the seal part can also be prevented at the time of bearing failure. Thus, this roller is really earth-friendly and also superior in fire prevention than conventional type.

4. Special Rollers

Roller with tighter sealing, particularly effective when used in dusty areas. Dimensionwise the same as the Standard model for interchangeability.

Return roller for heavy load.

Tiếng Việt

Tiếng Việt